For this 9th loop, very interesting topics have been submitted on our platform.

Discover here all the topics and which partners they are looking for and connect on our free platform to put your pledges.

What are the alternatives to Teams & Co?

by Eric Schnyder, Sylvac SA (Swiss SME specialized in high-precision measurement instruments)

Goal

The project aims to identify, test, and document concrete and viable alternatives to Microsoft Teams and the broader Microsoft ecosystem. Beyond collaboration and telephony, the goal is to provide SMEs, public institutions, and associations with tools that ensure digital sovereignty, interoperability, privacy, and cost control. The work will follow four steps: mapping functional needs, identifying unbiased alternatives, testing selected solutions, and creating a practical guide with a shared test environment to support other organizations in their transition.

Partners wanted

This initiative should be led by a diverse, open, and unbiased team with expertise in information systems, cybersecurity, IT governance, UX/UI design, and open innovation. We aim to co-create with partner organizations that are genuinely motivated to explore alternatives to Microsoft, while maintaining strong digital collaboration. We are seeking 3 to 5 companies willing to test these alternatives, along with contributors skilled in system administration, IP telephony, and UX/UI.

Breaking the Tariff Wall – A Swiss Tech Alliance for US Market Access

by Fabian Käser (Ctrl-Alt-Del GmbH, strategy & diversification consultant for SMEs)

Goal

Breaking the Tariff Wall – The project addresses the 39% US tariffs that threaten Swiss export-oriented SMEs and the high-tech industry (precision, machine tools, enabling tech). The aim is to develop legally sound and practical strategies to reduce tariff burdens, secure market access, and preserve customer relationships in the US. Through collective expertise, the project will design optimized supply chains, explore alternative trade routes, and build a collaborative alternative for knowledge sharing and joint solutions.

Partners wanted

We are seeking SMEs, manufacturers, suppliers, industry chambers, and trade associations, as well as experts in trade law, customs tariffs, logistics, and international supply chains. Active participation is key to co-developing sustainable strategies that mitigate the tariff challenge.

Swiss-made Intelligent Chatbot for Industry

by Eric Schnyder, Sylvac SA (Swiss SME specialized in high-precision measurement instruments)

Goal

The project aims to co-develop a smart, multilingual, and modular chatbot foundation tailored to the needs of Swiss SMEs. This shared solution will automate customer support, route requests efficiently, and reduce costs — all while ensuring data sovereignty through Swiss hosting. Each participating company will benefit from a common architecture and pooled development costs, while keeping its own operational data siloed and secure.

Partners wanted

3–5 SMEs interested in piloting the chatbot and contributing to co-development. Partner contributions will cover needs analysis, data for common scenarios, and user testing. Funding goals: CHF 25,000 → build a functional MVP, test with pilot SMEs, refine based on early deployment results

CyberSecLab — Co-developing Next-Gen Penetration Testing Methods

by Noria Foukia, prof at the HES-SO (MSE in Information and Cybersecurity)

Goal

The project aims to co-develop innovative approaches to penetration testing in collaboration with companies, going beyond standard services to address the real operational challenges of SMEs, startups, and public institutions. Guided by academic experts, cybersecurity Master students will:

Detect vulnerabilities in people, technologies, and systems; Improve incident response processes across the cyber kill chain; Test advanced Red Team / Blue Team strategies; Design and validate remediation approaches to restore systems securely.

Partners wanted

We are looking for companies (SMEs, startups, public operators, etc.) willing to share infrastructure contexts (confidentially), co-define and test new penetration testing strategies, provide regular feedback and collaborate in workshops. In return, partners benefit from tailored recommendations, prototypes, and demonstrators, as well as access to a cross-company community of practice. Funding goals: Crowdfunding will support the hiring of specialized teaching assistants (Master’s level in cybersecurity) to reinforce coaching and pedagogical support throughout the project.

FlowCharge: Inclusive e.carpooling

by Noria Foukia, HES-SO (HEPIA – Computer Science Department) & Pascal Lab

Goal

FlowCharge extends the existing open-source application FlowRide (https://flowride.org/) to accelerate the transition to electric mobility. The project will integrate a predictive application and intelligent infrastructure simulator into FlowRide, encouraging electric carpooling and optimizing the placement of charging stations based on real usage. This will foster sustainable mobility, collaborative economy, inclusivity, and optimal use of local resources. Funding goals: crowdfunding will support hiring a scientific collaborator to develop the FlowCharge extension with Pascal Lab, following an open-source approach, build a charging station prediction system for drivers integrated into FlowRide, create a planning tool for charging station managers to select optimal locations in urban areas

Partners wanted

We are looking for public partners (municipalities, electricity suppliers, charging station operators) and private partners (charging station providers, car park owners with charging facilities) who want to actively promote electric mobility. Partners will help define needs, share anonymized data, and co-develop inclusive, low-carbon transport strategies.

Electrodeposition of Gold Alloy with Tungsten from Aqueous Solutions

by Pierre-Antoine GAY (Professor at Haute Ecole Arc Ingénierie)

Goal

The project targets the development of a process for electrodeposition coatings (from 1 to 10 microns) of gold alloys including tungsten. The study of electrochemistry through cathodic reactions is the heart of this study. A latest generation potentiostat will be used to determine the reduction potentials of tungsten salts in an aqueous medium. The increasing of hardness and wear resistance of electrodeposit gold alloys coatings is the first aim of this project.

Partners wanted

A lot of applications like watch industry, jewelry or electronic contact are targets. The industrial partners participating in the project will supply their sample and will be evaluating the coatings properties during the research.

Precision Ultrasonic In-Situ Measurement of Workpiece Thickness and Geometry

By Raoul Roth (RhySearch)

Goal

Assess the feasibility of using ultrasonic sensors for in-situ measurement of workpieces during or between machining operations for selected user cases. This includes evaluating technical limits, achievable precision (targeting < 10 µm), geometric measurability beyond simple thickness (e.g., curvature, steps), and the ability to perform both absolute and relative measurements. The study should also consider environmental factors, system integration, and practical implications for machine tool operation.

Partners wanted

Collaboration with sensor providers and machine tool manufacturers will be sought to ensure practical relevance.

SkillCraft@Work: Digital Upskilling at the Workplace

by Sarah Rochat (Haute Ecole spécialisée bernoise (BFH))

Goal

Develop a workplace-based technical education initiative that enables existing Swiss employees to acquire digital skills necessary for today’s evolving work environment. The long term goal is to develop and implement a workplace-based program that teaches digital skills such as computer thinking and programming fundamentals, to current Swiss employees, enabling companies to upskill their workforce internally rather than relying solely on external hiring. This addresses the technical staff shortage by creating a pipeline of technically capable workers who already understand the industrial context.

Partners wanted

We are looking to build a consortium of companies that would be interested in participating to the program. Our goal is to first better understand the needs of the industry to define the targeted skills set, the best pedagogical approach and the needed partners in terms of expertise and technology.

Surface functionalization of the powder particles

by Oksana Banakh (Haute Ecole Arc Ingénierie)

Goal

The project targets a developing of an ALD coating process for depositing ultrathin oxide layers (a few tens of nm) to functionalize powder particles. Atomic Layer Deposition (ALD) is a vacuum coating process able to deposit uniform ultrathin oxide layers on (almost) any object. ALD can be succesfully used to cover microscale particules of any nature (metallic, ceramic) providing that they resist to 150°C. The advantages of this process are: – possibility to deposit ultrathin layers (min.5 nm) and to control the coating thickness (+/- 2 nm); – reduced process pressure (the ALD does not need a high vacuum); – perfectly uniform layer thickness on 3D objects ALD coatings are mostly oxides (TiO2, Ta2O5, ZnO, SiO2). These compounds are non-toxic and bioresorbable (important in pharma applications). The coated powder properties (sticking behaviour, dissolution) will be evaluated by the industrial end-users (in house).

Partners wanted

The project targets the developing of a coating process to functionalize powder particles. Anticipated applications are thought to be related to pharmacology, but not exclusively. The industrial partners participating in the project will supply their powder and will be evaluating the powder properties after the coating process.

Predictive Management of Unwanted Particles in Laser Printing and Processing

by Constant Rieille and Sylvain Le Coultre (Haute Ecole spécialisée bernoise (BFH))

Goal

This project aims to demonstrate the correlation between real-time in-situ particle detection and the final quality of laser-manufactured parts, enabling predictive management of particle-induced defects. It exploits a unique and innovative monitoring system developed by BFH spin-off OGURION, which detects and analyzes micrometer-sized spatter during laser processes such as laser powder bed fusion (LPBF), laser cutting, and welding. By linking detected particles with final part defects using techniques like X-ray microtomography, the system provides a scalable, compact, and robust solution for quality assurance, process optimization, and defect prevention. Designed for seamless integration into industrial laser machines, it offers a powerful tool for next-generation laser-based manufacturing environments.

Partners wanted

Potential applications include quality assurance, process optimization and defect prevention in additive manufacturing and other laser-based manufacturing environments. In case of success, this project could lead to the development of a unique, competitive accessory product dedicated to the predictive quality management of spattering redeposited particles defects in 3D printed, Laser Powder Bed Fusion and laser-worked parts available for the project partners.

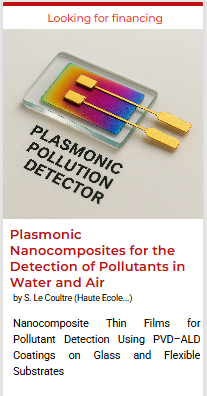

Plasmonic Nanocomposites for the Detection of Pollutants in Water and Air

by Sylvain Le Coultre (Haute Ecole spécialisée bernoise (BFH))

Goal

Develop a novel plasmonic sensor based on nanocomposite thin films for the detection of contaminants, such as heavy metals like mercury (Hg²⁺), lead (Pb²⁺) or cadmium (Cd²⁺) in water or air environments. These contaminants pose significant risks to health and ecosystems, and there is a growing need for simple, real-time, and robust detection methods. Several mechanisms, such as reduction and immobilization have already shown potential for local detection and even remediation of pollution. Our versatile deposition equipment and expertise in tuning optical properties of nanocomposite films allow us to tailor the sensor surface for selectivity via simple surface chemistry, without requiring biological recognition element. This makes the platform ideally suited for low-cost environmental monitoring and easy integration into inline or portable devices.

Partners wanted

We are open to collaboration with industrial stakeholders in water, microelectronics, or pharma, but also with public agencies (e.g., OFEV, cantonal labs).

Feedback loop control for L-PBF and EHLA copper coatings on titanium

by Enrico Tosoratti (inspire AG) and Kugler Bimetal SA of Geneva

Goal

Address critical challenges in coating titanium components with copper-based alloys by developing an automated, real-time in situ monitoring system. Additive manufacturing (AM) technologies, such as High Speed Laser Cladding (EHLA) offer the advantage of creating complex geometries at minimal additional cost, often referred to as « complexity for free. » However, existing alloys used in AM processes often exhibit inadequate material and interface properties, leading to defects such as cracks and pores. This project aims to overcome these issues by enhancing the quality of multimaterial components, with a specific focus on copper-based coatings on titanium components.

Partners wanted

Industrial partners interested in coating technologies, specifically in defect detection and quality assurance in AM processes. Partners showing interest in developing and integrating real-time monitoring systems for manufacturing.

AI Meets No-Code: Simplifying Robotics for Smarter Manufacturing

by Michael Jakob (Haute Ecole spécialisée bernoise (BFH))

Goal

Improve the usability and learnability of the no-code robotic interface by integrating AI assistance, which will guide technicians and simplify complex programming tasks. Additionally, the project aims to simplify and optimize programming by reducing the time required for task reprogramming and minimizing errors, while also providing support for complex decision-making. Finally, the goal is to increase flexibility and cost-efficiency by enabling faster adaptation, allowing a single robotic cell to handle multiple tasks, and reducing overall costs for diverse industrial applications.

Partners wanted

To implement this AI-enhanced no-code robotic system, we need collaboration from manufacturers to define use cases, technology providers for system integration and testing, and AI experts to develop the assistant’s architecture.

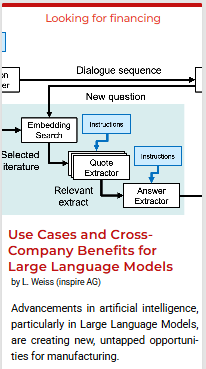

Use Cases and Cross-Company Benefits for Large Language Models

by Lukas Weiss and Markus Maier (inspire AG)

Goal

Provide industry participants with a comprehensive understanding of how LLMs can be applied. Through collaborative meetings, we will explore specific use cases tailored to each participant’s operations. The project will culminate in a proof of concept that demonstrates the tangible application of LLMs with real-world relevance and practical utility, involving the partners who are willing share the necessary data on an exemplary basis.

Partners wanted

The idea adresses manufacturers, machinery suppliers, suppliers of these branches, suppliers of software solutions storing relevant data, or offering commercial solutions of LLMs and comparable software tools.